Nadeed Company

Home Of Machines

Fiber laser cnc

LF-3015P model, in line with the latest technological advancements, further enhances its user experience with an intuitive control panel, allowing operators to easily navigate through the machine's functions. The outward moving table is designed for efficiency, significantly reducing the time taken for the loading and unloading process of metal plates.

Robotic welding is the use of automated robotic arms to perform welding tasks with precision and consistency. It integrates advanced technologies such as arc welding, laser welding, resistance welding, and spot welding to enhance productivity, reduce errors, and improve workplace safety. A robotic welding system consists of key components including an industrial robot arm that handles the welding torch with high precision, a welding power supply that provides the necessary voltage and current, a wire feeder and welding torch that deliver the welding material and execute the weld, positioners and fixtures that secure and manipulate workpieces for optimal welding angles, a control system and software that programs and controls the robotic movements, and sensors and vision systems that enable real-time monitoring and adjustments. The benefits of robotic welding include increased efficiency with faster welding speeds reducing production time, improved quality with consistent and precise welds, reduced labor costs by minimizing reliance on skilled manual welders, enhanced safety by reducing worker exposure to heat, fumes, and sparks, and better material utilization by minimizing waste and rework. Robotic welding is widely used in industries such as automotive for frame and body welding, aerospace for precision welding of aircraft components, shipbuilding for heavy-duty metal welding, construction and infrastructure for steel structures and pipelines, and manufacturing for various metal fabrication applications. Future trends in robotic welding include AI and machine learning integration to enhance automation and real-time adjustments, the rise of collaborative welding robots (cobots) that work alongside human welders, and advancements in laser and ultrasonic welding for improved precision and speed.

The LF3015CN model, in line with the latest technological, further enhances its UI with an intuitive control panel, allowing operators to easily navigate through the machine's functions. The machine's external display is a distinct feature that provides clear and detailed visualization of the machine's operations, enabling operators to monitor and control the processes effectively.

LF3015MB cutting machines offer high precision cutting, producing clean, burr-free edges that require little to no finishing work. This increased accuracy reduces the need for additional processing, saving time and resources. These machines are capable of cutting a wide range of materials, including stainless steel, carbon steel, aluminum, and other metal alloys.

Services

Machines Supply

Milling Machines, Fiber Laser Cutting Machines, Press Brake Machines Welding Machines, Welding Robots .

Tools Supply

Milling Tools, Fiber laser Consumables, Press brake Tools

Maintenance

Maintenance & Repairing all CNC Machines

Articles

Understanding Fiber Laser Cutting Machines: An Essential Guide By Nadeed CNC

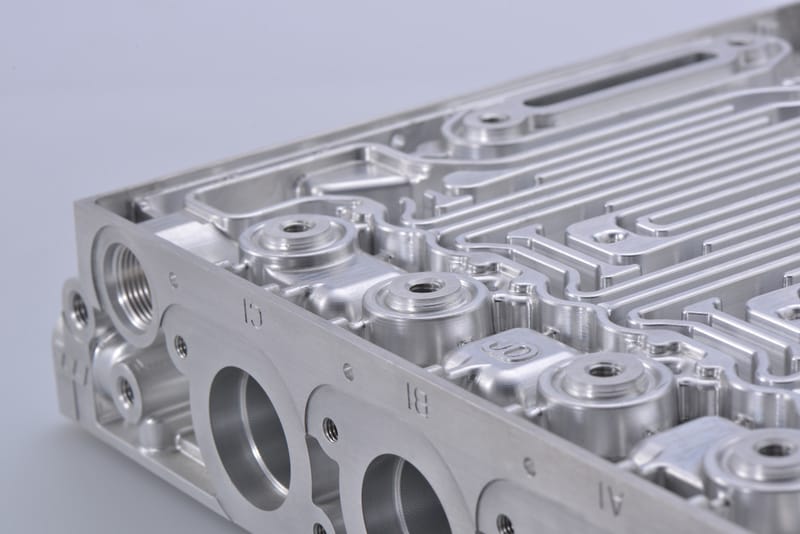

CNC Milling Machines: Unraveling the Technology Behind Precision Manufacturing By Nadeed CNC

Press Brake Machines: Shaping the Future of Sheet Metal Fabrication By Nadeed CNC

Fiber Laser Head: The Heart of Precision Laser Cutting By Nadeed CNC

AC Servo Motors: Powering Precision in Automation

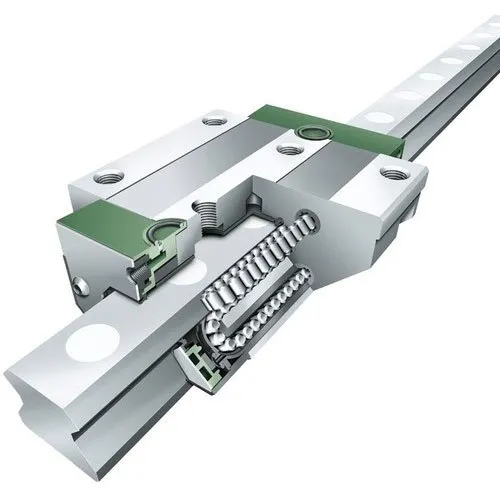

Linear Guide Rails and Bearings: Simplifying Motion in Precision Machinery

Contact us

- Office no 809, Al-Rossais Commercial Center, 3857 Olaya St, Riyadh 6468, Riyadh 12211

- +966-0569777728

+966-0569777728

+966-0569777728 +966-0569777781

+966-0569777781- Info@Nadeed-cnc.com

- 9am to 6am Sunday to Thursday

Welcome to Nadeed, sales teams Email: Info@nadeed-cnc.com